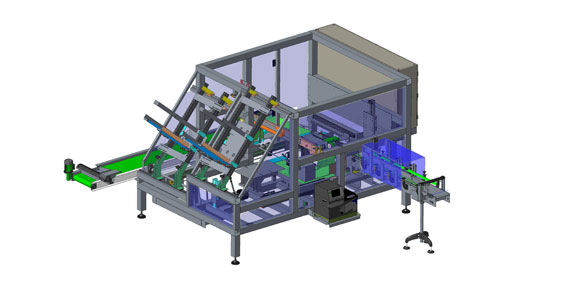

The retail ready packaging case packer machine created by Spark is part of a growing sector of the market for display cartons with lids that protect products from the inside, while allowing for rapid opening and an easy and simple shelving system.

Because of its different feed options, the bottom and lid case packer can be used with various products and to produce different types of packaging including cartons, vacuum bags, tins, jars, square bottom bags and padded parcels.

The main packaging material used is microfluted, corrugated or folding cardboard. The case packer machine created by Spark has, however, a major innovation compared to its competitors: it makes it possible to change the number of rows and the number of packages per row while using cardboard of the same dimension. By selecting a specialised programme, the machine is able to have products feeding from different levels depending on what the user wants. This is done without having to change any mechanical parts of the machine. This way, you can use the same cardboard to package a product in different carton types simply by selecting a different button.

FORMAT AND CHANGE OF FORMATSpark's case and tray packers can be designed according to the specific needs of a company. It was created as a modular design with interchangeable shaping heads. In this way, the cardboard can be differently shaped simply by changing these heads. At the same time, the supply stores are built to allow a wide range of adjustment.

OPERATION The case packer machine for retail ready packaging functions in a very simple way. It picks up the cardboard forms for the lid and bottom from their respective feeders, groups the products into the bundle that needs to be put inside the cardboard and proceeds to shape the bottom and lid around the prepared bundle. The completed carton then moves out of the machine. Average productivity: 60 strikes per minute. MACHINE CONSTRUCTION:

ADDITIONAL OPTIONSThe machine comes with several standard features. However, you can add options upon request: 1- Label Maker 2- Feeding Belts

SUPPLYThe case packer machine comes tested and complete with all software and technical documentation in accordance with currently effective regulations and CE marking. The main packaging material used is microfluted, corrugated or folding cardboard. The case packer machine created by Spark has, however, a major innovation compared to its competitors: it makes it possible to change the number of rows and the number of packages per row while using cardboard of the same dimension. By selecting a specialised programme, the machine is able to have products feeding from different levels depending on what the user wants. This is done without having to change any mechanical parts of the machine. This way, you can use the same cardboard to package a product in different carton types simply by selecting a different button. FORMAT AND CHANGE OF FORMAT Spark's bottom and lid machine can be designed according to the specific needs of a company. It was created as a modular design with interchangeable shaping heads. In this way, the cardboard can be differently shaped simply by changing these heads. At the same time, the supply stores are built to allow a wide range of adjustment. OPERATION The case packer machine functions in a very simple way. It picks up the cardboard forms for the lid and bottom from their respective feeders, groups the products into the bundle that needs to be put inside the cardboard and proceeds to shape the bottom and lid around the prepared bundle. The completed carton then moves out of the machine.

Average productivity: 60 strikes per minute. |

Industrial pasta machine

Make your Request

Case packer machine |